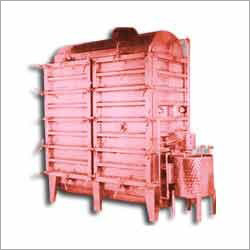

Cabinet Type Machine

Price 800000 INR/ Piece

MOQ : 1 Piece

Cabinet Type Machine Specification

- Driven Type

- Electric motor

- Output Frequency

- 50 Hz

- Function

- Automated glue dispensing and assembling

- Dimension (L*W*H)

- 1800mm x 950mm x 1750mm

- Weight

- 650 kg

- Glue Type

- Hot melt adhesive

Cabinet Type Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Ahmedabad

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Letter of Credit (L/C), Cash in Advance (CID), Cheque

- Supply Ability

- 02 Pieces Per Month

- Delivery Time

- 01 Months

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Western Europe, Middle East, Central America, South America, Asia, Eastern Europe, North America, Australia, Africa

- Main Domestic Market

- All India

About Cabinet Type Machine

| Machine Type | Semi-Automatic |

With the support of our experts and sophisticated in-house facilities, we have been able to offer an array of Cabinet Type Machine. Our offered machines are precisely manufactured using the best quality material and advanced technology under the guidance of our skilled personnel. These machines are inspected on well-defined parameters of quality, in order to offer flawless range at clients' end.

Features:

- Sturdy construction

- Minimal maintenance

- User-friendly

Product Details:

- Suitable for a wide variety of yarns including wool, acrylic, viscose, ramie, cotton and their blends

- Complete process of scouring, steaming, bleaching, dyeing and softening can be done in a single operation

- Direct and indirect heating systems are available to different requirements

Superior Efficiency for Industrial Operations

With a processing capacity of up to 1500 pieces per hour, this cabinet type machine optimizes production lines in packaging, electronics, and furniture sectors. The digital PLC controller ensures accurate automation, while advanced safety features safeguard operators during intensive operations. Its robust stainless steel cabinet withstands demanding environments, making it dependable for continuous use.

Advanced Glue Dispensing Technology

Equipped with a state-of-the-art automated hot melt adhesive system, the machine delivers uniform glue application for consistent assembly quality. The integrated electric motor and PLC control panel allow operators to customize settings for various materials, enhancing productivity and minimizing waste during large-scale manufacturing processes.

Safe and Quiet Operation

This machine is engineered to operate at noise levels below 75 dB, ensuring a comfortable workspace. In addition, emergency stop and overload protection add extra layers of safety. The temperature-controlled environment (0C to 50C) supports reliable performance across seasons, making it versatile for different industries.

FAQs of Cabinet Type Machine:

Q: How does the Cabinet Type Machine improve assembly productivity in manufacturing industries?

A: By automating glue dispensing and assembling tasks, the machine significantly increases throughputprocessing up to 1500 pieces per hour. Its digital PLC controller streamlines operations and reduces manual labor, leading to higher efficiency and more consistent product quality.Q: What safety features are integrated into this machine for operator protection?

A: The machine is equipped with emergency stop and overload protection mechanisms. These ensure immediate shutdown during hazardous situations and prevent electrical or mechanical overloading, enhancing user safety during operation.Q: When is this machine suitable for use in industrial settings?

A: It performs optimally in environments with ambient temperatures between 0C and 50C. The machine is ideal for high-volume production lines in industries such as packaging, electronics, and furniture where automated assembly and glue application are fundamental.Q: Where can the Cabinet Type Machine be utilized?

A: This machine finds applications in packaging plants, electronics assembly units, and furniture manufacturing facilities. Its robust design and versatile functionality make it suitable for a wide range of industrial locations across India and globally.Q: What process does the machine follow for automated glue dispensing and assembling?

A: The machine uses a digital PLC controller to automate tasks. Hot melt adhesive is dispensed through a precise nozzle system, and components are accurately assembled using electrically driven mechanisms, resulting in uniform and reliable bonding.Q: How does the design of the cabinet contribute to operational reliability?

A: Constructed from stainless steel, the cabinet provides excellent durability and resistance to corrosion and wear. This ensures the machine remains efficient and maintains high performance, even in demanding industrial environments.Q: What are the main benefits of using this machine for manufacturers and exporters?

A: Manufacturers and exporters benefit from increased output, consistent quality, improved worker safety, and reduced noise. Its adaptability to various assembly applications streamlines production processes, enabling businesses to meet large orders promptly.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free